The Ultimate Guide to Quail Farming: Housing, Equipment & Management

Breed Selection:

Brown quail (80% farmer preference) for disease resistance; adult weight 130g, daily feed 22g, egg weight 12g (40 eggs/lb).

Precision Management:

Chicks require 35-37°C + 16-20hr light; adults thrive at 20-26°C/50-60% humidity + 8-10hr light. Activate fans/cooling pads >29°C in summer; natural ventilation suffices in winter.

Cage Design:

6-tier system (370mm spacing), unit size 1.2m×0.65m, density 86.7cm²/bird (90 birds/layer). Feed side height:

125mm; egg collection side: 175mm (external belt).

Barn Layout:

Even-column setups recommended (6-column width: 12.5-13.5m, height ≥3.3m). A 90m×13.5m barn holds 217,000 birds with 22 fans + 132m² cooling pads.

Biosecurity:

Isolated zones prevent predators; music reduces stress; never mix with poultry.

Efficiency Formula:

Stocking capacity = (Barn length - Equipment zones) ÷ 1.2m/unit × Columns × 90 birds/layer × 6 tiers

1. Quail Breeds & Basic Metrics

Top Breeds

Brown Quail:

Preferred by 80% farmers for disease resistance & adaptability.

White Quail:

Chinese White Quail variant, leaner body composition

Key Metrics

| Parameter | Value |

|---|---|

| Adult Weight | 130g/bird |

| Egg Weight | 12g/egg (40 eggs/lb) |

| Daily Feed Intake | 22g/bird |

2. Precision Environmental Control

Critical Parameters

| Growth Stage | Temperature | Humidity | Light Hours |

|---|---|---|---|

| Chicks (0-3 wks) | 35-37°C | 60-70% | 16-20 hrs |

| Adults | 20-26°C | 50-60% | 8-10 hrs |

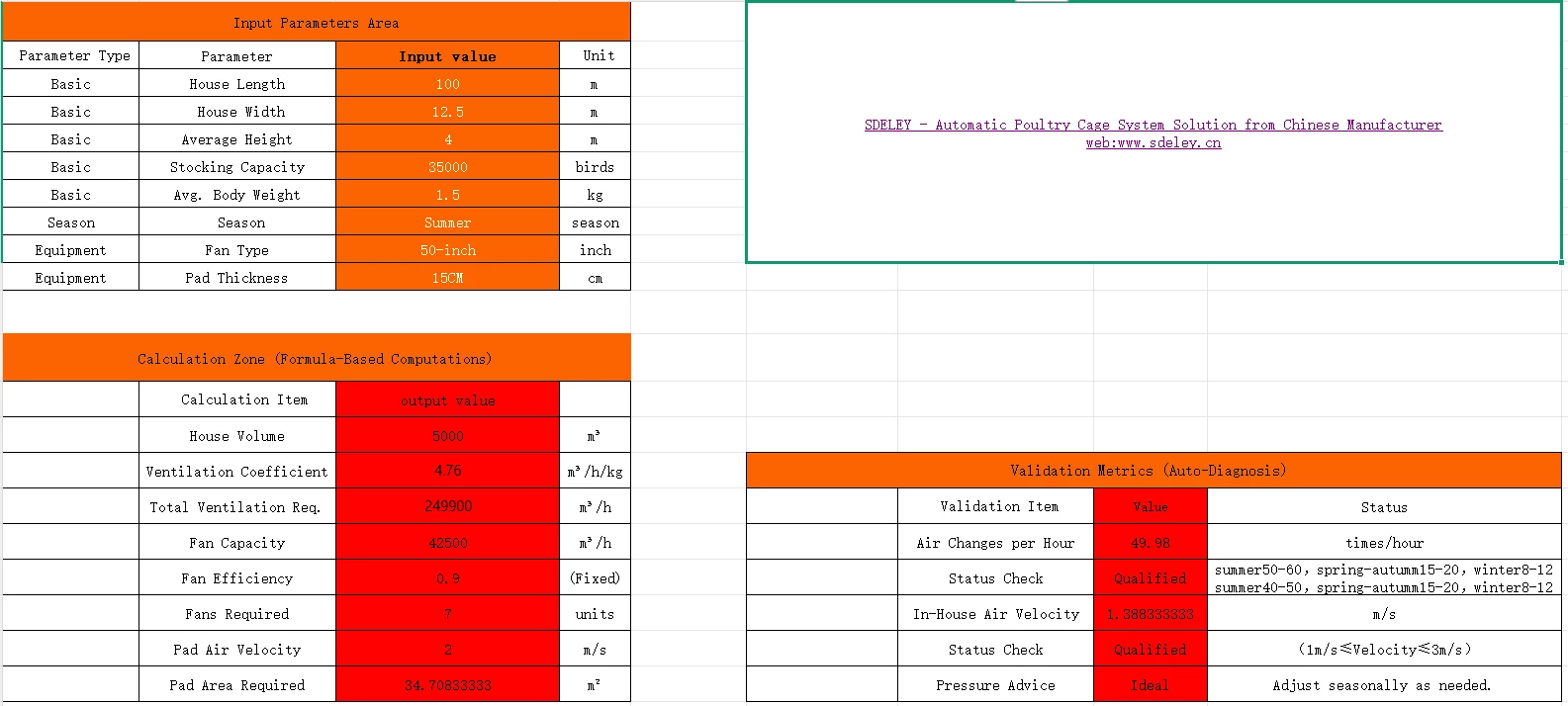

Ventilation Protocol

- Summer: Activate fans + cooling pads when >29°C

- Winter: Natural ventilation sufficient

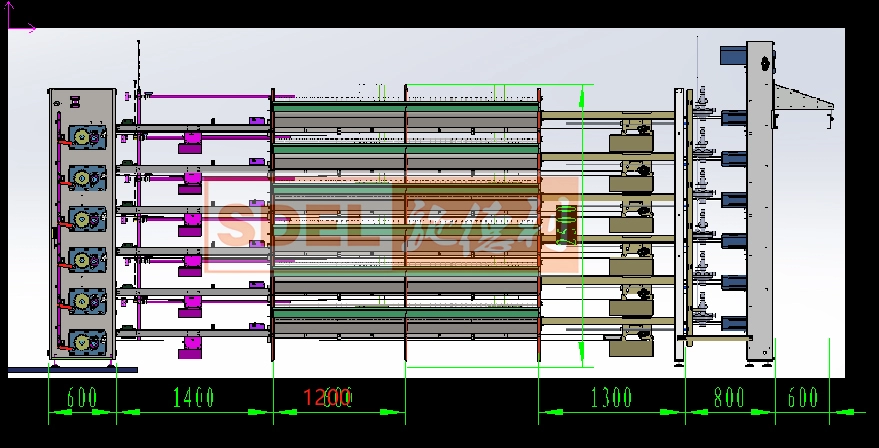

3. Cage System Design

Optimal Layout

- Cage Dimensions: 1.2m (L) × 0.65m (W) × 0.25m (H)

- Stocking Density: 86.7 cm²/bird (90 birds/layer)

- Tier Configuration: 6-layer system, 370mm inter-tier space

Engineering Specs

| Component | Specification |

|---|---|

| Cage Frame | Galvanized steel (2mm wire) |

| Feeding Side Height | 125mm |

| Egg Collection Side | 175mm (external egg belt) |

| Water System | Nipple drinkers (egg side) |

4. Housing & Equipment Standards

Barn Dimensions

| Layout | Width | Height |

|---|---|---|

| 4-column | 9-10.5m | ≥3.3m |

| 6-column | 12.5-13.5m | ≥3.3m |

| 8-column | ≈17m | ≥3.3m |

Automation Systems

- Feeding: Single-side system spanning 2 cage units

- Egg Collection: External belt (reduces breakage)

- Manure Removal: Scraper belts under each tier

5. Facility Planning Case Study

Sample Barn: 90m (L) × 13.5m (W) × 3.5m (H)

Cage Units Calculation:

90m - 1.5m (manure channel) - 1.2m (ditch) - 1.4m (manure machine clearance)

- 1.3m (egg collector space) - 1.5m (egg collection line) = 83.1m

Usable length: 83.1m ÷ 1.2m/unit = 69 units

Total birds: 69 units × 6 columns × 90 birds/layer × 6 layers = 223,560 quail Climate Equipment:

- Fans: 22 units (1/10,000 birds)

- Cooling Pads: 132m² (fan area × 6)

6. Biosecurity & Welfare Practices

- Noise Control: Play soft music to reduce stress

- Predator Proofing: Rodent/snake-proof foundations

- Species Segregation: Never house with chickens/ducks

- Light Management: Gradual dimming to prevent panic

Why This System Works

A Chinese farm using this model achieved:

✅ 95% egg integrity rate

✅ 18% lower feed waste

✅ 5% higher survival rate vs open systems

Ready to optimize your quail operation? Request our cage design templates or ventilation CFD analysis! 🐤

Keywords:#quailcagesystem #QuailFarming #PoultryEquipment #CageDesign #AnimalHousing #QuailEggProduction