Complete Guide to Layer House Equipment Systems

Design, Installation & Efficiency Standards

Introduction

The layer house equipment system comprises Cage Group Systems, Feed Silo & Feeding Systems, drinking systems, ventilation & cooling systems, lighting systems, manure removal systems, egg collection & central conveying systems, and control systems. Designed for water/energy conservation, improved environment, easy disinfection, labor efficiency, stress reduction, and disease prevention, this guide details critical considerations for procurement, design, and installation.

1. Cage Group System

Core Standards

- Material: Hot-dip galvanized steel frames, alloy wire mesh floors (20+ year lifespan)

- Critical Details:

- Smooth zinc coating (no burrs)

- Elastic floor mesh with optimal slope

- Secure cage doors

- Seamless trough joints

- Egg roll nets with flat transitions

- Feather-friendly feeding grid spacing (≥7cm/bird)

- Anti-deviation manure belts

- Egg breakage rate <0.5%

- Tier Height: 690mm recommended (vs. 568/600mm) for enhanced airflow

- Density: ≥490 cm²/bird (Hy-Line Brown)

Visual Reference:

- High-clearance cages (690mm) → ↑Air velocity for summer cooling

- Low-clearance cages (600mm) → Limited thermal regulation

2. Feed Silo & Feeding System

Components & Specs

| Subsystem | Requirements |

|---|---|

| Feed Conveying | Silos, augers, hoppers, drives + fault alarms |

| Feeding Methods | Broadcast, chain, spiral, or back-hopper systems |

| Troughs | Hot-galvanized/SS construction; bird-capacity optimized hoppers |

| Levelers | Adjustable by feeding phase; travel speed: 3-6 m/min |

| Silos | 3-day capacity (0.65t/m³ density); corrugated galvanized steel; structural legs |

| Accuracy | ≤0.5% weighing error; UV-resistant conveying pipes |

3. Drinking System

Smart Water Management

- Components: Tanks, pressure reducers, filters, meters, medicators, nipple drinkers (with catch cups), anti-perch devices

- Critical Features:

- Flow-regulated nipples (≥50ml/min)

- Multi-stage filtration

- Proportional dosing (pressure-independent)

- Sectional control + low-pressure alarms

- Thermal-expansion resistant joints

- End-line visibility tubes

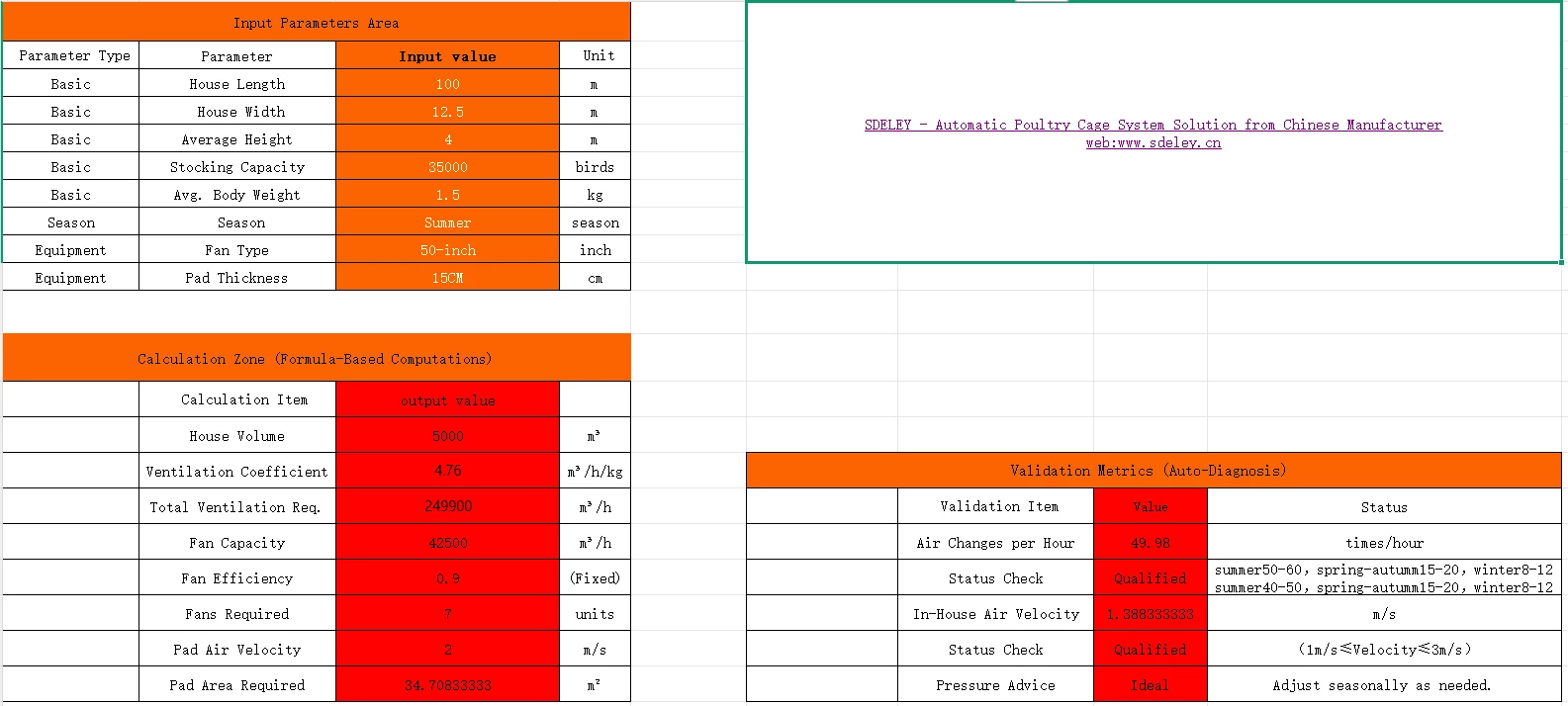

4. Ventilation & Cooling System

Wet Pad-Fan System (Most Efficient)

- Pad Specifications:

- Location: Clean zone sidewalls (>3m from cages)

- Height: 0.4-0.6m above floor + air deflectors

- Water Quality:

- pH 6-9; hardness <40000ppm mixed salt

- Algae prevention: Covered reservoirs + daily drying cycles

- Sizing Formulas:

- Fans = Total Airflow (m³/h) ÷ [Single Fan Capacity (m³/h) × Efficiency Factor (0.9)]

- Pad Area (m²) = Total Airflow (m³/h) ÷ [3600 × Pad Air Velocity (m/s)]

- Example: 10,000 birds @40°C → 3 fans (50″) + 20m² pads

You can refer to this article for reference:

《Comprehensive Design Guide for Layer House Ventilation Systems》

5. Lighting System

Precision Control

- Components: Dimmable LED fixtures (10-20W), IP67 waterproof connectors, NH3-resistant

- Key Parameters:

- 1-100% dimming + red/blue spectrum switching

- Fixture spacing: 3m (staggered heights)

- Biological Impacts:

- ⚠️ Avoid 50Hz flicker (causes stress/pecking)

- Blue light: Calming (broilers)

- Red light: Stimulates egg production

6. Manure Removal System

- Belt speed: 3-5 m/s → 20-30 min/100m house

- Critical: Belt tension control to prevent deviation

7. Egg Collection & Conveying System

Automated Workflow

- Components: Cage belts → In-house collectors → Central conveyors → Grading

- Specifications:

- Cage belt speed: 1 m/min

- Main line speed: 5-6 m/min

- ±0.5% counting accuracy

- Fault auto-detection (e.g., belt detachment)

- Installation: Elevated central lines + accessible service points

8. Smart Control System

Integrated Monitoring

- Core Functions:

- Real-time alerts (temp/gas/sensor faults)

- Data logging (feed/water/egg production)

- Environment control (light/ventilation automation)

- Centralized farm management (PC/mobile)

- Automation:

- Dynamic inlet/ventilation adjustment

- Wet-pad activation logic

Technical Compliance:

ISO 15999 Poultry Equipment Standards | ASABE EP484.2 Ventilation Guidelines